Advanced Materials Lab

OPWL 529

Background

For my Needs Assessment project, I was incredibly lucky to work with the Boise State University (BSU) Advanced Materials Lab (AML). The AML researches dangerous and nuclear materials under extreme conditions. Safety is critically important in this sort of environment so we were asked to do a needs assessment of the lab's current safety practices and make recommendations on ways to improve their safety outcomes.

Methodology

Needs Assessment Model

Our original plan followed Van Tiem's Human Performance Technology needs assessment model, involving Performance Analysis, Cause Analysis, Intervention Selection, Implementation, and Evaluation. However, the AML at Boise State University was an exemplary performer according to all of our data sources so we were forced to adjust our methodology a few weeks into the project. The typical needs assessment model requires identifying and addressing problems in an organization which wouldn't work for us since this lab was doing nearly everything so well.

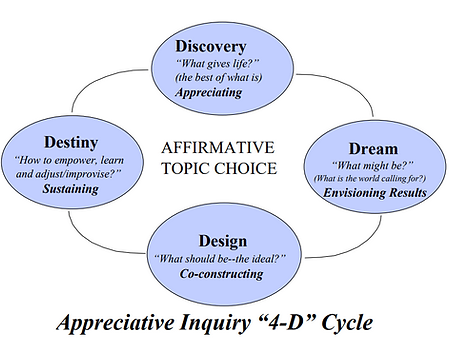

As a result, we pivoted to an Appreciative Inquiry (AI) approach. This model focuses on what the organization is doing well, strengthening these aspects and applying lessons from these successes elsewhere. AI's "4Ds" – Discovery, Dream, Design, and Destiny – guided our process, revealing elements that contribute the most to exemplary performance and allowing for their replication and support for even greater outcomes.

The Appreciative Inquiry approach differs from standard needs assessment models in its focus and process. It begins by understanding the lab's current state and identifying its most successful practices. We then work with the lab's stakeholders to envision an ideal future for the lab, unrestricted by current constraints. The approach utilizes the lab's existing strengths as a foundation for designing strategies that bridge the gap between its present state and this envisioned future, leveraging these strengths to guide the lab towards its ideal potential.

Source. From Performance improvement/HPT model: Guiding the process by Van Tiem, Moseley, & Dessinger. (2012)

Source. From A Positive Revolution in Change: Appreciative Inquiry by Cooperrider & Whitney. (2005).

Process

The first step to understanding the organization and why it works so well was an extensive data collection and analysis process.

Data Collection and Analysis

To structure our assessment of the Advanced Materials Lab (AML), we utilized Chevalier's updated Behavior Engineering Model (BEM) to gain a comprehensive understanding of the organization.

To gather data, we conducted extensive interviews with lab personnel. The insights from these interviews were organized into an interview code book structured around the BEM. This organization allowed us to map our findings onto the BEM neatly, ensuring a clear and comprehensive view of the AML's operations.

We then used a fishbone diagram to visualize the key processes and habits contributing to the lab's exemplary safety performance. This diagram served as a valuable tool in identifying the most impactful factors in the lab's success.

Findings

Current State and Cause

We found that the Advanced Materials Lab at BSU excels in multiple areas.

Training at the lab is dynamic, with a focus on progressive learning and peer teaching, fostering a culture of shared responsibility and safety. The lab culture emphasizes open communication, critical thinking, and viewing mistakes as learning opportunities, with senior staff leading by example.

Procedures include regular safety walkthroughs and active student involvement in creating and updating SOPs. Third-party audits provide external validation, while strict lab hygiene and tool management ensure a safe working environment.

The strong community within the lab enhances team dynamics and reaffirms their commitment to safety. Personal and professional development are closely linked to safety adherence, enhancing career prospects. The hiring policy focuses on safety-mindedness, ensuring a good cultural fit. Staff management is adaptable and prioritizes well-being, while the hands-on learning approach deepens understanding and vigilance towards safety.

Ideal State

Part of the interviewing process involved engaging in a creative exercise with our subject matter experts where we envisioned an ideal state for the lab. This exercise revealed a few key takeaways that we believe could propel the lab toward even better outcomes:

-

E-Learning Integration: The idealized version of the lab has learnings available on demand, available at any time and when staff need them.

-

Dynamic Yearly Safety Seminars: The ideal version of the lab has yearly safety seminars that are continuously updated and challenge experienced staff.

-

Cultivated Lab Culture: The ideal lab supports community building which is currently done haphazardly through deliberately building traditions, rituals, and bonding experiences beyond lab work.

-

Enhanced Mentorship Program: The ideal lab has a structured mentorship process with dedicated resources and regular knowledge-sharing meetings.

-

Robust Succession Planning: The ideal lab prepares future lab leaders in advance to ensure continuity in operations during staff transitions.

-

Intensified Third-Party Audits: The idealized version of the lap participates in regular audits, including simulated emergencies to improve preparedness.

-

University Support for Safety Initiatives: Ideally, there is increased backing from the university for safety equipment, training programs, and staffing.

Intervention Selection

The intervention selection for the Advanced Materials Lab was the final step in our needs assessment, aimed at aligning the lab's current operations with its ideal state.

Selection Process

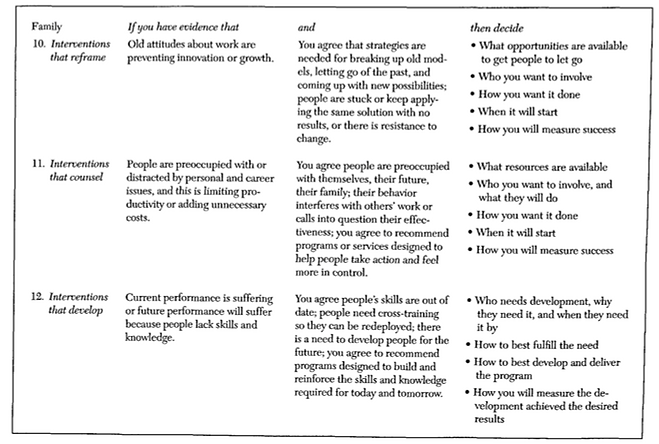

We utilized Judy Hale's Intervention Selection Model to categorize potential changes and align them with the lab's strengths.

Source. From The Performance Consultant's Fieldbook: Tools and Techniques for Improving Organizations and People by Judith Hale. (2006)

Following this, we conducted a feasibility analysis using Siko's I-2 Intervention Matrix. This process helped us prioritize interventions by assessing their impact against invasiveness.

Final Recommendation

Our final recommendation for the Advanced Materials Lab focused on:

-

Formalizing the mentorship program

-

Building a strategic plan for succession and recruitment

-

Performing reciprocal safety audits with external partners

We selected these interventions to enhance safety standards, improve knowledge transfer, and cultivate a culture of continuous learning. They align with the lab's objectives and are designed to integrate smoothly with existing operations, minimizing disruption.

Additionally, we proposed creating a safety rubric based on AML's practices to guide other labs at Boise State University, ensuring a comprehensive and standardized approach to lab safety across the university's lab network.

You can download the entire report here.

Reflections

Initially, we struggled with applying the standard Van Tiem's HPT model, expecting to uncover problems and answer preconceived questions. However, the unique circumstance of the lab being an exemplary performer led us to rethink our approach and adapt. This project taught us the value of flexibility and open-mindedness in needs assessment, pushing us to develop innovative solutions tailored to the specific context of the AML.

I feel so much gratitude for the opportunity to work alongside my talented team members: Mariola Diawara, Damien Miggins, and Andrew Clark. Their patience, expertise and collaborative spirit were instrumental in successfully dealing with the challenges we had during this project. And I'm grateful to the Advanced Materials Lab for giving me the opportunity to work with their talented and professional staff and learning about the incredible work that they do.

References

Chevalier, R. (2003, May/June). Updating the behavior engineering model. Performance Improvement, 42(5), 8–13. https://doi.org/10.1002/pfi.4930420504

Research and Economic Development. (n.d.). About Boise State Research. Boise State University. Retrieved December 7, 2023, from https://www.boisestate.edu/research/

College of Engineering. (n.d.). Home. Boise State University. Retrieved December 7, 2023, from https://www.boisestate.edu/coen/

Advanced Materials Laboratory. (n.d.). Home. Boise State University. Retrieved December 7, 2023, from https://www.boisestate.edu/aml/

Bentkowski, E., & Yamaga, M. (2006). Exploring appreciative inquiry. Volume 4, Issue 2, Fall 2006, Volume 4(Issue 2). Retrieved from https://jstor.org/stable/community.31298168

College of Engineering Safety website. Retrieved October 18, 2023, from https://www.boisestate.edu/coen-safety/

Cooperrider, D., & Whitney, D. (2005). A positive revolution in change: Appreciative inquiry. In The Change Handbook: The Definitive Resource on Today's Best Methods for Engaging Whole Systems (p. 87).

Dessinger, J. C., Moseley, J. L., & Van Tiem, D. M. (2012). Performance Improvement/HPT Model: Guiding the process. Performance Improvement, 51(3), 10–17. https://doi.org/10.1002/pfi.20251

Hale, J. A. (2006). The performance consultant’s fieldbook: Tools and techniques for improving organizations and people. Pfeiffer.

Siko, J. P. (2013). Using the I² Intervention Matrix to Select the Best Course of Action. Performance Improvement, 52(10), 23–26. https://doi.org/10.1002/pfi.21378

Watkins, R., West-Meiers, M., & Visser, Y. L. (2012). A guide to assessing needs: Essential tools for collecting information, making decisions, and achieving development results. World Bank.